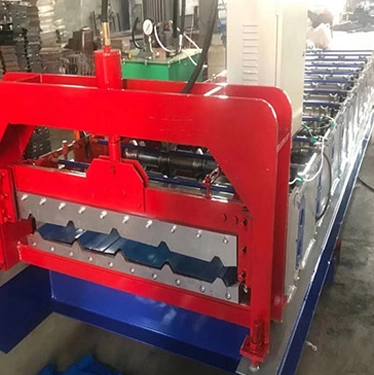

The 840 single-layer tile pressing machine is composed of unloading, forming, and post-forming cutting. The products produced have smooth and beautiful appearance, uniform paint texture, good strength, and long service life. They are widely used in industrial and civil buildings, such as factories, warehouses, and locomotive garages, hangars, gymnasiums, exhibition halls, theaters and other rooms and walls. The center line of the upper and lower rolls of the tile press should be on the same plane line, based on the center wheel, the flatness is not more than 1mm, the gap between the upper and lower rolls of each row is equal, and the gap deviation is +0.1mm. Debug with conventional gauges or feeler gauges.

The 840 type tile press equipment is divided into three parts, the roller table forming part, the pressing part and the cutter part. The forming part of the roller table is driven by a motor, and the chain drives each roller to rotate. In the pressing part, the hydraulic cylinder drives the mold to move up and down, which can press the color steel into many sections, which look like glazed tiles. The cutter part is driven by the hydraulic cylinder to move the cutter up and down, which can cut the colored steel tiles.

To debug the 840 type color steel tile press, first measure the four corners of the front and rear rows of the color steel tile press equipment from the big frame to the height of the upper end of the bottom shaft, and then arrange them in a row to find a line Straighten, check whether the lower axis is in a straight line, and adjust the left and right sides of the lower axis to be horizontal. Find the center of the color steel tile equipment, then tighten the lock nuts on both sides, draw a straight line in front and back of the center of the middle wheel, and adjust the gap between the upper and lower shafts, and then adjust the machine along the straight line.

Reducer: | 1:29 |

Shaft diameter: | 1 inch |

Inverter: | 7.5KW |

Number of forming rows: | 16 rows |

Large frame material: | 350H steel |

Middle plate thickness: | 16mm |

Chain size: | 1 inch chain |

Molding speed: | 16M/min |

Motor power: | 5.5KW |

Feed thickness: | 0.4mm-1mm |

Feeding width: | 1M |

Forming width: | 840 |

Machine weight: | 6T |

Equipment size: | 9500mm*1600mm*1500mm |

Electric control system: | PLC computer control of the whole machine |

Service life: | More than 2 million meters have been measured. |

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision equipments insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română