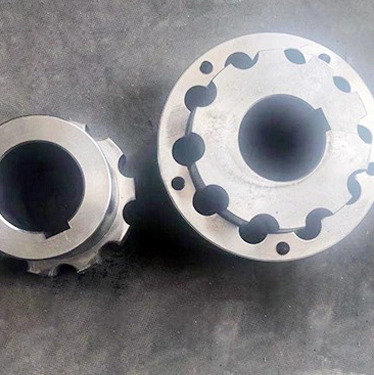

The ZL elastic pin gear coupling is a pin made of several non-metallic materials, placed in the mating hole between the two halves of the coupling and the inner surface of the outer ring, and the torque is transmitted through the pin to realize the two half-coupling connection, the elastic pin gear coupling has the following characteristics:

1. The transmission torque is large, and most of the turning diameters are smaller than the gear coupling at the same torque, the volume is small, and the weight is light, which can partially replace the gear coupling.

2. Compared with the gear coupling, the elastic pin gear coupling has a simple structure, fewer components, and is more convenient to manufacture, without the need for gear processing machine tools.

3. It is easy to maintain and has a long service life. The nylon pin can be replaced by removing the baffle.

4. Nylon pins are self-lubricating materials, no lubrication is required, which not only saves lubricating oil, but also purifies the working environment.

5. Poor vibration reduction and high noise.

ZL type elastic pin gear coupling has good performance in compensating axial, radial and angular axis deviation, good vibration damping performance, simple structure, stable operation, no noise, no lubrication, convenient maintenance, simple assembly or disassemble, good manufacturability, low cost, can be derived into a variety of structural forms, good versatility, wide application range, easy to popularize. One of the outstanding advantages of this coupling is that it only needs one centering installation. When changing the elastic element, there is no need to move the half coupling, which can reduce auxiliary man-hours and improve production efficiency. When assisting, it improves production efficiency, and is especially suitable for installations where axis alignment is difficult, and it is required to minimize auxiliary working conditions. The elastic pin gear coupling is a new type of coupling in our country, which concentrates the advantages of different structures of the current standard elastic coupling, for example, it has the advantages of the quincunx elastic coupling: Due to its simple structure, it is relatively safe when squeezed. It overcomes the shortcomings of the quincunx elastic coupling: when changing the elastic element, the half-coupling must be moved. The double-flange quincunx elastic coupling can replace the elastic element without moving the half-coupling, the structure is complicated and the cost is high, increase the mass and moment of inertia, and the application range is limited. When transmitting the same torque, the radial dimension is much smaller than that of the elastic sleeve pin coupling, with light weight and small moment of inertia.

Specification | Nominal torque Tn(N.m) | Allowable speed [n]r/min | Shaft hole diameter d 1 d2 | Fitting length of shaft hole | D | B | Moment of inertia Kg.m 2 | Wight m Kg | |

Y model | J1 model | ||||||||

L | L 1 | ||||||||

ZL1 | 100 | 4000 | 12 14 | 32 | 27 | 76 | 42 | 0.0004 | 0.80 |

16 18 | 42 | 30 | |||||||

19 | |||||||||

20 22 | 52 | 38 | |||||||

24 | |||||||||

ZL2 | 250 | 4000 | 16 18 | 42 | 30 | 92 | 50 | 0.003 | 3.23 |

19 | |||||||||

20 22 | 52 | 38 | |||||||

24 | |||||||||

25 28 | 62 | 44 | |||||||

30 32 | 82 | 60 | |||||||

ZL3 | 630 | 4000 | 25 28 | 62 | 44 | 118 | 69 | 0.011 | 6.57 |

30 32 | 82 | 60 | |||||||

35 38 | |||||||||

40 42 | 112 | 84 | |||||||

ZL4 | 1600 | 4000 | 40 42 | 112 | 84 | 158 | 89 | 0.046 | 14.8 |

45 48 | |||||||||

50 55 | |||||||||

56 | |||||||||

60 | 142 | 107 | |||||||

ZL5 | 4000 | 4000 | 50 55 | 112 | 84 | 192 | 89 | 0.114 | 24.8 |

56 | |||||||||

60 63 | 142 | 107 | |||||||

65 70 | |||||||||

71 75 | |||||||||

80 | 172 | 132 | |||||||

ZL6 | 6300 | 3300 | 60 63 | 142 | 107 | 230 | 111 | 0.28 | 42.5 |

70 71 | |||||||||

75 | |||||||||

80 85 | 172 | 132 | |||||||

90 95 | |||||||||

ZL7 | 10000 | 2900 | 70 71 | 142 | 107 | 260 | 113 | 0.56 | 66.3 |

75 | |||||||||

80 85 | 172 | 132 | |||||||

90 95 | |||||||||

100 110 | 212 | 167 | |||||||

ZL8 | 16000 | 2500 | 80 85 | 172 | 132 | 300 | 136 | 1.21 | 107.3 |

90 95 | |||||||||

100 110 | 212 | 167 | |||||||

120 | |||||||||

125 130 | 252 | 202 | |||||||

ZL9 | 2500 0 | 2300 | 90 95 | 172 | 132 | 335 | 146 | 1.98 | 140.9 |

100 110 | 212 | 167 | |||||||

120 | |||||||||

125 | 252 | 202 | |||||||

ZL10 | 31500 | 2100 | 130 140 | 212 | 167 | 355 | 151 | 2.85 | 180.9 |

150 | |||||||||

100 110 | 252 | 202 | |||||||

120 | |||||||||

125 | 302 | 242 | |||||||

130 140 150 | |||||||||

ZL11 | 40000 | 2000 | 160 170 | 212 | 167 | 380 | 170 | 3.9 | 219.3 |

110 120 | 252 | 202 | |||||||

125 | |||||||||

130 140 150 | 302 | 242 | |||||||

160 170 180 | |||||||||

ZL12 | 63000 | 1700 | 130 140 | 252 | 202 | 445 | 183 | 9.2 | 371.4 |

150 | |||||||||

160 170 | 302 | 242 | |||||||

180 | |||||||||

190 200 | 352 | 282 | |||||||

ZL13 | 100000 | 1500 | 150 | 252 | 202 | 515 | 218 | 15.6 | 470 |

160 170 | 302 | 242 | |||||||

180 | |||||||||

190 200 | 352 | 282 | |||||||

220 | |||||||||

240 | 410 | 330 | |||||||

ZL14 | 125000 | 1400 | 170 180 | 320 | 242 | 560 | 218 | 27.8 | 708 |

190 200 | 352 | 282 | |||||||

220 | |||||||||

240 250 | 410 | 330 | |||||||

260 | |||||||||

ZL15 | 160000 | 1300 | 190 200 | 352 | 285 | 590 | 238 | 33.4 | 768 |

220 | |||||||||

240 250 | 410 | 330 | |||||||

260 | |||||||||

280 300 | 470 | 380 | |||||||

ZL16 | 250000 | 100, 0 | 220 | 352 | 282 | 695 | 262 | 69.9 | 1169 |

240 250 | 410 | 330 | |||||||

260 | |||||||||

280 300 | 470 | 380 | |||||||

320 | |||||||||

340 | 550 | 450 | |||||||

ZL17 | 315000 | 950 | 240 250 | 410 | 330 | 768 | 282 | 122.7 | 1664 |

260 | |||||||||

280 300 | 470 | 380 | |||||||

320 | |||||||||

340 360 | 550 | 450 | |||||||

380 | |||||||||

ZL18 | 400000 | 850 | 250 260 | 410 | 330 | 860 | 300 | 202.7 | 2193 |

280 300 | 470 | 380 | |||||||

320 | |||||||||

340 360 | 550 | 450 | |||||||

380 | |||||||||

400 420 | 650 | 540 | |||||||

ZL19 | 630000 | 750 | 280 300 | 470 | 380 | 970 | 320 | 341.2 | 2901 |

320 | |||||||||

340 360 | 550 | 450 | |||||||

380 | |||||||||

400 420 | 650 | 540 | |||||||

440 450 | |||||||||

ZL20 | 1000000 | 650 | 320 | 470 | 380 | 1156 | 351 | 710 | 4251 |

340 360 | 550 | 450 | |||||||

380 | |||||||||

400 420 | 650 | 540 | |||||||

440 450 | |||||||||

460 480 | |||||||||

500 | |||||||||

ZL21 | 1600000 | 530 | 380 | 550 | 450 | 1440 | 355 | 1948 | 7514 |

400 420 | 650 | 540 | |||||||

440 450 | |||||||||

460 480 | |||||||||

500 | |||||||||

530 560 | 800 | 680 | |||||||

600 630 | |||||||||

ZL22 | 2000000 | 500 | 420 440 | 650 | 540 | 1520 | 396 | 2931 | 10148 |

450 460 | |||||||||

480 500 | |||||||||

530 560 | 800 | 680 | |||||||

600 630 | |||||||||

670 710 | 900 | 780 | |||||||

750 | |||||||||

ZL23 | 2500000 | 460 | 480 500 | 650 | 540 | 1638 | 430 | 4379 | 13026 |

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision equipments insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română