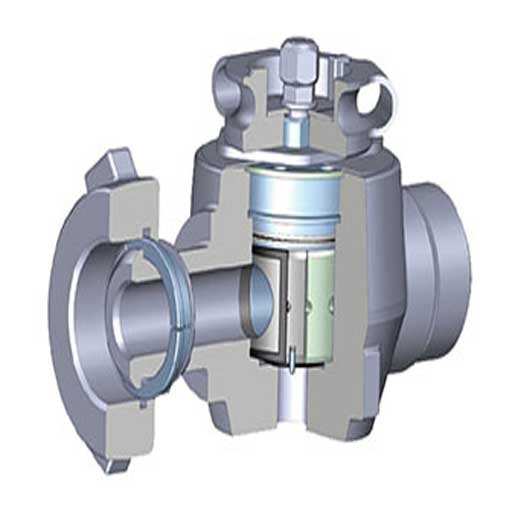

The plug body of cylindric plug valve is in cylindrical shape, which makes up of a sealing pair with the tapered hole surface of valve body. Cylindric plug valve is generally sealed in four ways, namely, sealant, valve plug expansion, O-ring, eccentric plug wedges into valve seat.

Cylindrical plug valve with a Teflon sleeve and plug seal in the valve body, which is pressed into the valve body with a compression nut, and the expansion force of the Teflon sleeve is used to seal.

The use of cylindrical plug valves depends to some extent on the seal between the plug and the valve body. Generally cylindrical plug valves often use four sealing methods, namely, using a sealant, using a plug expansion, using a 0-ring seal, and using an eccentric plug wedge seat seal. The sealing of the cylindrical lubrication plug valve is achieved by the sealant between the valve plug and the valve body. The sealant is injected into the sealing surface through the valve plug rod by bolts or injection guns, so when the valve is in use, it can effectively compensate for the lack of sealing by injecting a supplemental sealant.

Lubricated plug valves are particularly suitable for abrasive media because the sealing faces are protected from contact with the flowing medium in the fully open position. However, lubricated plug valves are not suitable for throttling because the sealant is flushed from the exposed seal surface during throttling so that the seal of the seat is restored each time the valve is closed.

The disadvantage of this valve is that the addition of the sealant often requires manual work. The use of automatic injection can overcome this disadvantage, but the cost of adding equipment needs to be increased. Once the valve is cleaned or repaired due to lack of maintenance or due to improper selection of sealant, or crystallization between the sealing faces and the valve plug not rotating in the valve body.

Cylindrical plug valve with a Teflon sleeve and plug seal in the valve body, which is pressed into the valve body with a compression nut, and the expansion force of the Teflon sleeve is used to seal .

Nominal Bore: 1"~3"

Working Pressure : 2000psi ~ 15000psi

Temperature Level: –75° F ~ +250° F

Body Material: AA、BB、CC、DD、EE、FF、HH

Specification Level: PSL1~PSL3G

Performance Level: PR1~PR2

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision equipments insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română