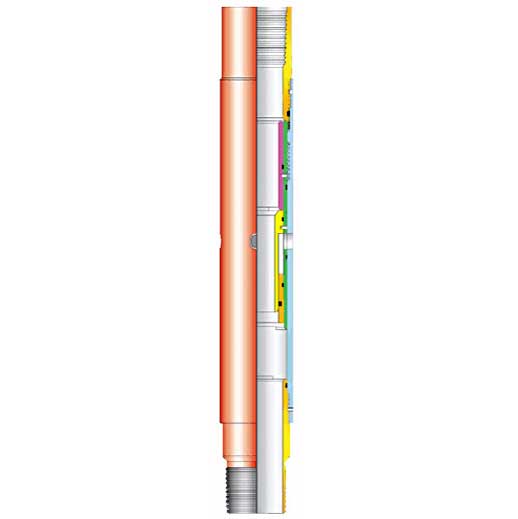

The multi-stage cementing collar provides an effective, economical way to cement one or more specific casing intervals or to cement upper zone saft era lower zone has been cemented. The collar should be used with centralizers aboce and below and a cementing basket positioned below the ports. The operation of the collar is simple and reliable. It features a double locking mechanism consisting of a snapring lock and ball lock system to assure that the ports are permanently locked closed after cementing is completed. Internal parts are designed to lock to prevent rotation during drill out and are constructed of easily drillable materials.

The use of closed structure, can be achieved after the closure of a permanent self-locking.

Open, close the action, there is no small cavity liquid compression problem.

The inner diameter of the upper and lower fittings is the same as the inner diameter of the bushing, but less than the inner diameter of the bushing. When the bushing is operated, the bushing can be effectively protected to prevent damage.

All attachments are made of rubber / aluminum material with good drillability, anti-rotation mechanism and convenient drilling.

With a replacement plug open, can be used for continuous cementing operations.

Stage cementing collar are recommended in the following situations:

A well whose cement hydrostatic head is greater than formation pressure at some intervals but not at other intervals

Lighter cement is required in the low pressure formation to avoid formation fracture and reduce the possibility of leakage

Heavy cement is required in the high pressure formation to maintain control of the well

In deep hot holes, the time required to pump the required mass and amount of cement is limited, so it is best to keep the slurry pumpable by reducing the total volume placed in a certain interval during any particular pumping operation.

When only certain parts of the well bore require zone isolation

Under the downhole conditions requiring different slurry mixtures to address the unique challenges of each segment and achieve the desired regional isolation integrity

In horizontal wells, the bend radius of the well requires cementing

There are two types of multi-stage cementing tools to choose from: blockage (free fall) or hydraulic opening (vacuum). All Halliburton stage cementing tools operate continuously at temperatures up to 275°F (135°C).

| Specifications,(in) | 51/2'' | T | 95/8" | 133/8" |

| Max OD., mm | Φ170 | Φ208 | Φ283 | Φ381 |

| Drill-out I.D., mm | Φ122 | Φ155 | Φ220 | Φ315 |

| Overall Length, mm | 1082 | 1182 | 1222 | 1280 |

| Rated Load, t | 140 | 170 | 210 | 300 |

| Sealing Capacity, MPa | 25 | 25 | 25 | 25 |

| Opening Pressure, MPa | 13 | 13 | 13 | 14 |

| Closing Pressure, MPa | 5 | 5 | 5 | 5 |

| Lower Sliding Sleeve I.D., mm | Φ85 | Φ115 | Φ176 | Φ203 |

| Upper Sliding Sleeve I.D., mm | Φ95 | Φ125 | Φ197 | Φ285 |

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision equipments insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română